Research & Development Report - Bottle Cutting Fixture

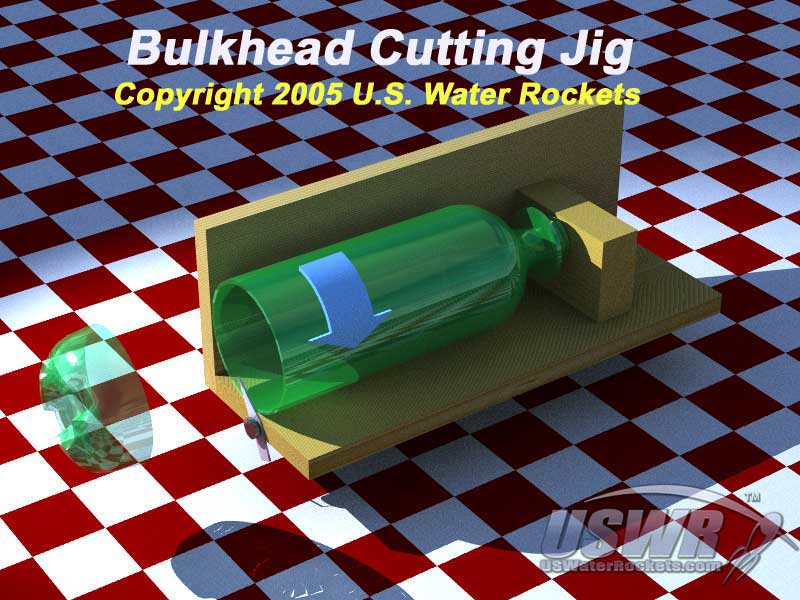

To aid in this endeavor, the Engineering team at U.S. Water Rockets has designed a very clever and simple fixture to assist in making the elusive perfect joints. A simplified version of this jig can easily be fashioned from common materials by any Water Rocket builder. All that is needed to form such a device is a few pieces of wood, a screw, and a sharp blade.

Assembly is easy. First, fasten two boards together to form a 90 degree angle, then the small blade (such as that from a razor knife) is screwed to the end of one of the boards. A third block of wood is then fastened to the inside of the angle to provide a stopping point at the intended length of the cut. A simple clamp can be used to hold this block in place so that the fixture can be reconfigured for different lengths of cut bottles or tubes.

The principal behind the device is simple. The bottle which is being used to cut a bulkhead or nozzle from is place in the inside of the angle of the fixture and pushed up against the stop block. The bottle is then rotated slowly as the knife blade is gently brought to contact with the side of the rotating bottle with increasing pressure. After a few turns, the cut is complete

The joint formed is perfect when the two pieces cut this way are overlapped by an even amount all the way around.

U.S. Water Rockets cautions that the knife blade is very sharp and this device should be used under adult supervision with proper safety measures, such as safety glasses. When the fixture is not in use, the blade should be removed or capped off with a block of wood or a large rubber pencil eraser to prevent injury.

If you are interested discussing or commenting on this article, please visit:

The Water Rocket Forum